Passivation

Passivation is a galvanic process for creating conversion layers. By treating metal surfaces with chrome(VI)-containing solutions, the corrosion protection and adhesion are increased. Aluminum, magnesium and zinc-coated steels are suitable for passivation. The layers which are less than 1 µm thick are electrically conductive and can be soldered. G.W.P. offers yellow passivation, green passivation and transparent passivation in accordance with DIN EN 12487. We can offer chrome(VI)-free alternatives (colorless) for orders in conformance with RoHS.

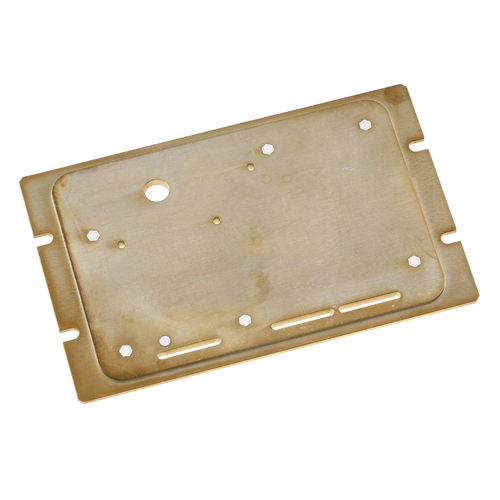

Passivation is particularly appropriate for aluminum components that must be conductively connected (housing parts, etc.).

Advantages

- Enhanced corrosion protection

- Improved adhesion of coatings

Services

- Dipping

- Basket and rack plated goods

- Max. 1,800 x 400 x 800 mm