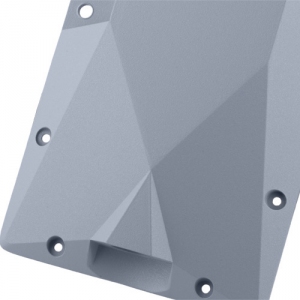

Powder coating

Powder coating or stoved enamel painting is a very high quality, environmentally-friendly coating method for satisfying a wide range of requirements and uses. Excellent adhesion, high chemical and thermal resistance and a favorable mechanical strength offer lasting protection against environmental influences and simplify cleaning. For decorative uses, coating powders are available for different gloss levels, different effects and different surface structures. Powder coated components can be machined; some powders can even withstand the subsequent shaping of the component.

To ensure high-quality, coating powders require proper pretreatment and the precise maintenance of process parameters. The EPS method with thermoset powders used by G.W.P. is suitable for decorative coatings that must satisfy high functional standards for scratch resistance or chemical resistance. Different powders are used depending on the purpose.

Properties of powder coatings

- Epoxy powder: Fine grain, closed, dense structure; thin layers are also possible. Not weather resistant; high decorative surface requirements are possible, for inside use

- Polyester powder: Coarse-grained, less of a closed, dense structure; thick layers, weather-resistant, restricted fineness for decorative uses, for outside use

- Mixed powders: A compromise between epoxy and polyester powders

- Two-layer method: A bottom coating of epoxy powder followed by a polyester powder coating; very resistant, requires twice as much time and effort

Coating powders come in all RAL colors and a wide range of qualities. G.W.P. offers economical powder coatings as well as powder coatings that meet the most stringent requirements. Special colors, glimmer effects, structures and special reflection values are possible. We require an additional coating drawing in order to produce partial coatings. Consult with us!