Rapid Manufacturing / Direct Manufacturing

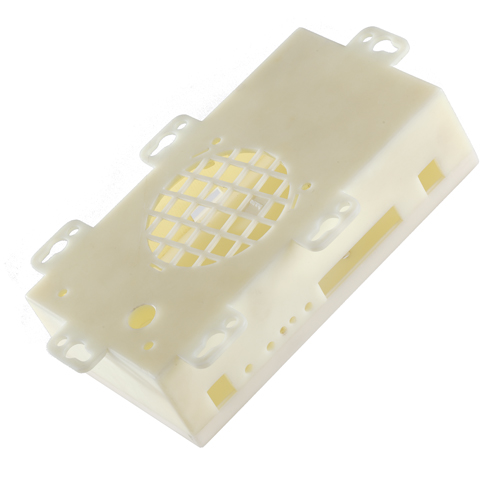

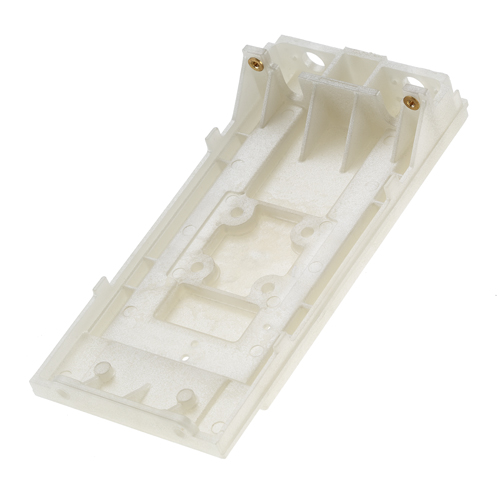

Rapid manufacturing (RM) or direct manufacturing (DM) includes different manufacturing methods for directly and quickly generating marketable components directly from CAD volume data. Rapid manufacturing uses the generative rapid prototyping method proven in prototype construction for automatic, layered production of components with complex geometries.

Advantages

The advantages of rapid manufacturing is the short product launch time, savings in comparison to conventional methods, and the minimization of time it takes for changes (no dies). An additional benefit of generative RP technologies (stereolithography or multi-jet modeling) is the economical creation of complex geometries. Greater complexity does not increase cost. The savings from rapid manufacturing depend on the batch size, component size, material availability and specific property requirements or long-term reproducibility and cannot replace conventional die-using methods in many cases.

Opportunities

Take advantage of rapid manufacturing to shorten the time to market and to minimize investment costs! Find out whether and which rapid manufacturing method is suitable for your project by filling out a detailed questionnaire or in a consultation discussion.

G.W.P. will manufacture small batches of marketable plastic and metal parts for you directly from CAD data. Contact us or send your RFQ with CAD files!