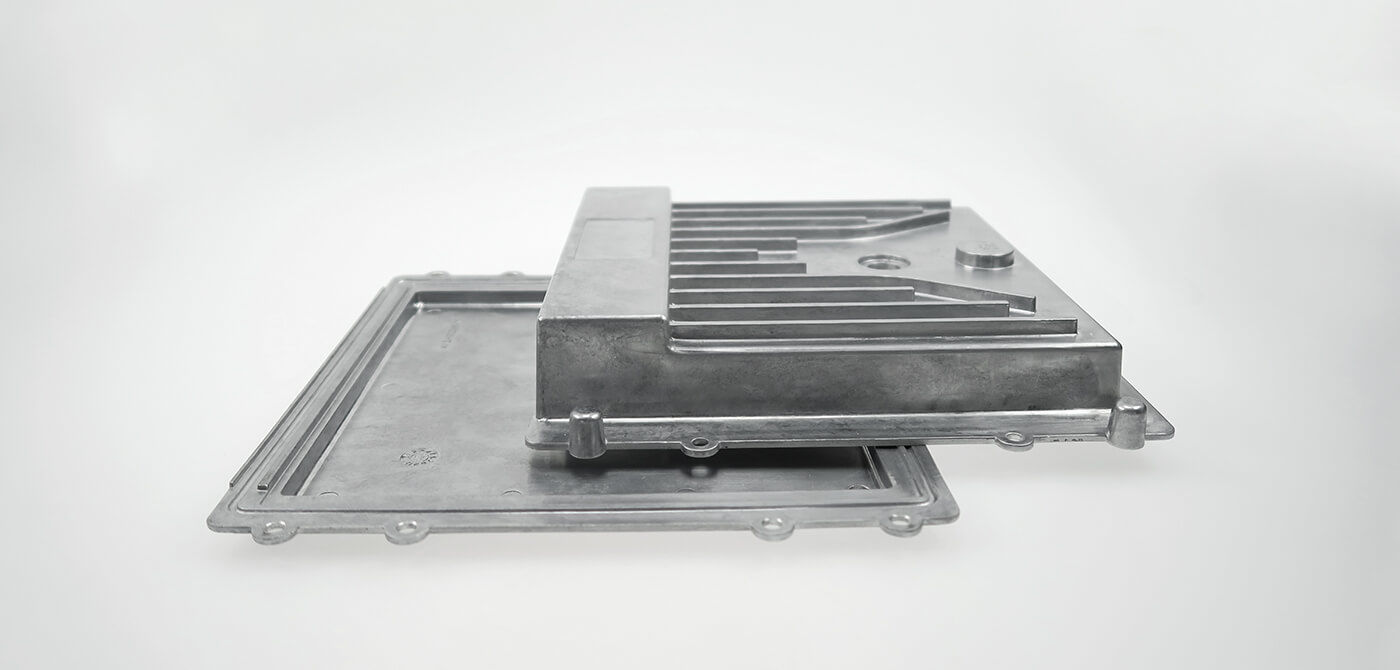

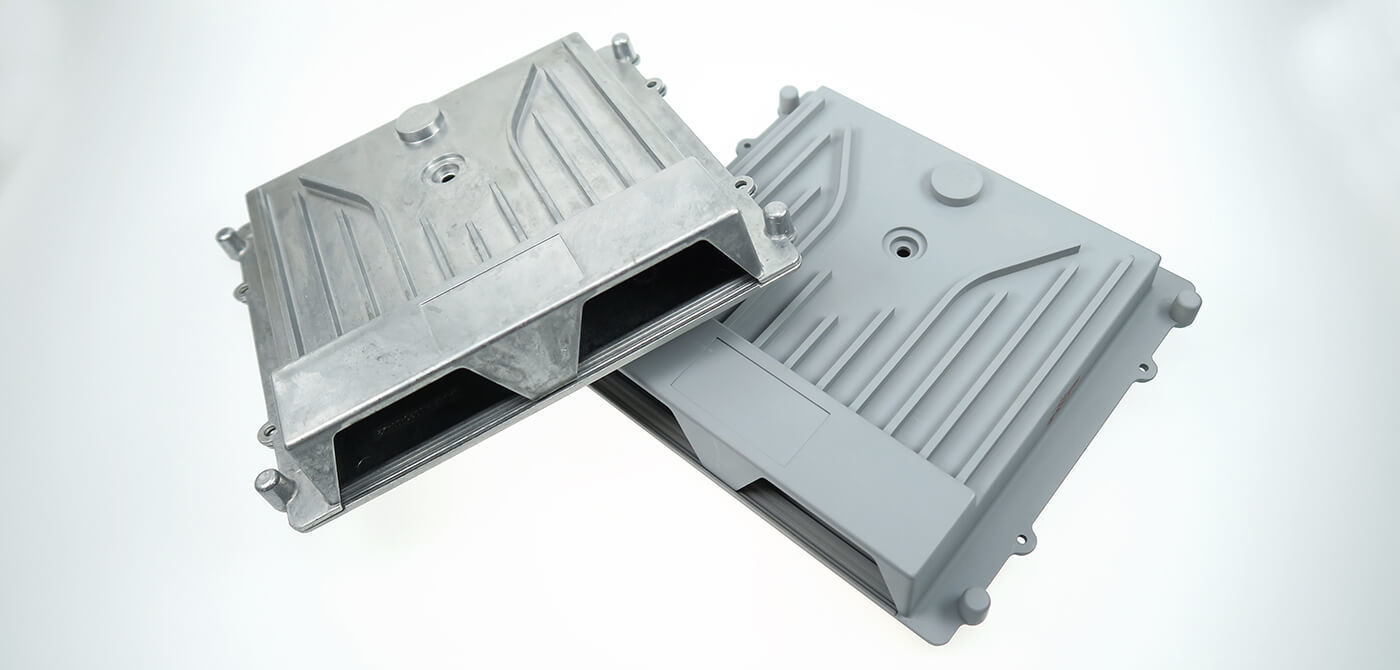

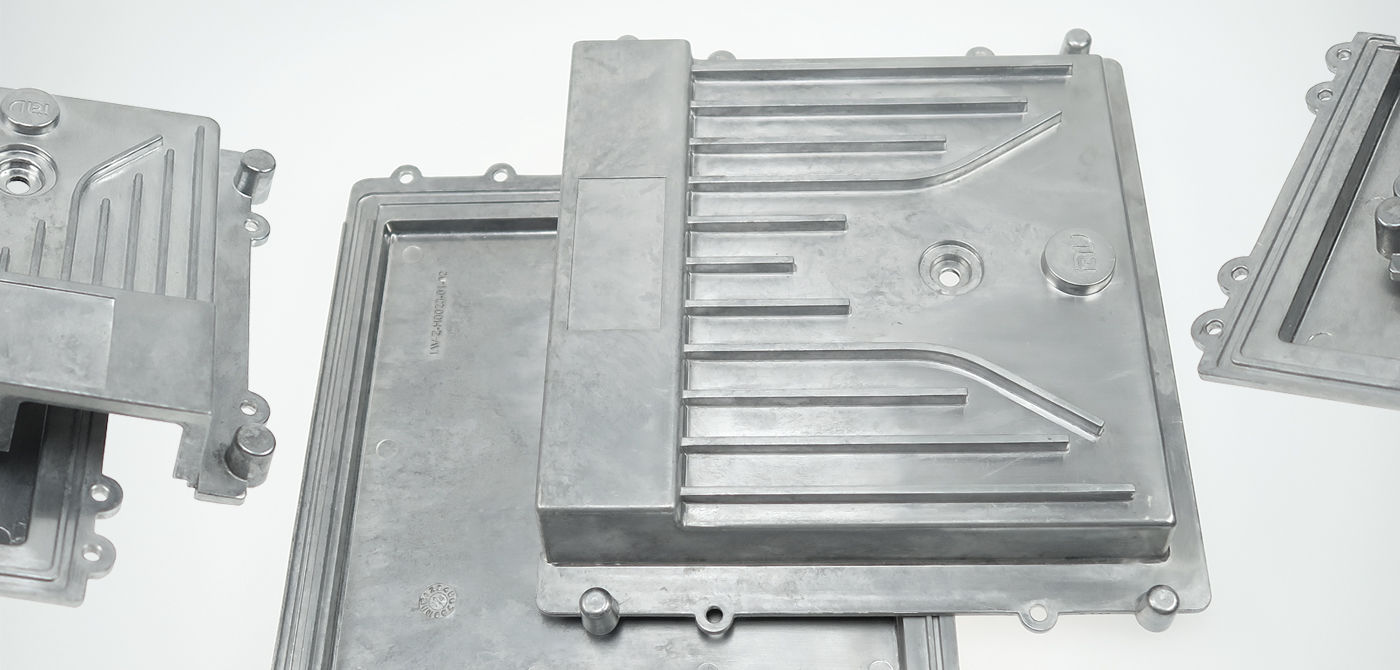

PROTO DIE – REAL DIE CASTING PROTOTYPES

We recommend our patented PROTO DIE,

if you want to develop a high-quality, thin-walled die-cast part cost-effectively and in a time-saving manner and require prototypes as well as pilot series.

Save time & costs, ensure quality

With the economical PROTO DIE process, you receive high-quality prototypes made of die casting within a few weeks - with workpiece properties as in series production. Not only do you optimize your component design for series production in die casting as early as possible, but you also shorten the product development process, lower your development costs and reduce the risks during product launch.

Close to series & adaptable

With PROTO DIE, the production of 1-3,000 parts from the same prototype mold is feasible. We already evaluate the molded parts for the future die casting process in the prototype phase. Experience and test results from the prototypes flow directly into the design of the subsequent series tool. With these empirical values, you gain time during mold creation and optimize the release process. With just a few adjustments, you can also use the PROTO DIE mold for pilot series production.

| Technical data | |

| Delivery time | First part from the tool already from 20 calendar days |

| Material | Aluminium, zinc, magnesium, brass |

| Feasible number of parts | 1-100 pieces (prototypes), 101-3,000 pieces (pre-series) |

| Tolerances | General tolerances for die casting. Fittings: possible with cnc processing |

| Max. dimension | Approx. 300 mm body diagonals R=√(a2+b2+c2) |

| Max. clamping force | 500 t |

| Finish | Painting, powder coating, anodizing and galvanic treatments |

| Postprocessing | CNC machining, trowalizing |

| Adjustments | Changes to the contour are possible within the tool life and depending on the design of the tool |

| Possible applications | In typical pre-series situations such as crash tests, EMC tests and for molded part optimizations |

PROTO DIE - Your benefits

- Reduced product development phase

- Rapid availability (samples & pre-production series from one tool; product tests and certifications take place before completion of the production tool)

- Elimination of cost-intensive, off-series test series (milled prototypes or produced from investment castings)

- Early, qualitative optimization of series technology

- Reduction of risks during product launch

NEED MORE INFORMATION?

Are you interested in the benefits and services of G.W.P. or do you want a customised offer? You can save time by ordering your quotes online. Please fill out the form - you can upload your data files of your project and get an individual offer.

Talk to us about your next project:

Phone: +49 3328.33066.0

Email: info@gwp-ag.com

Click here to fill out a short form that will help our sales team get to know your project: